By Kevin Haas

Rock River Current

Get our mobile app

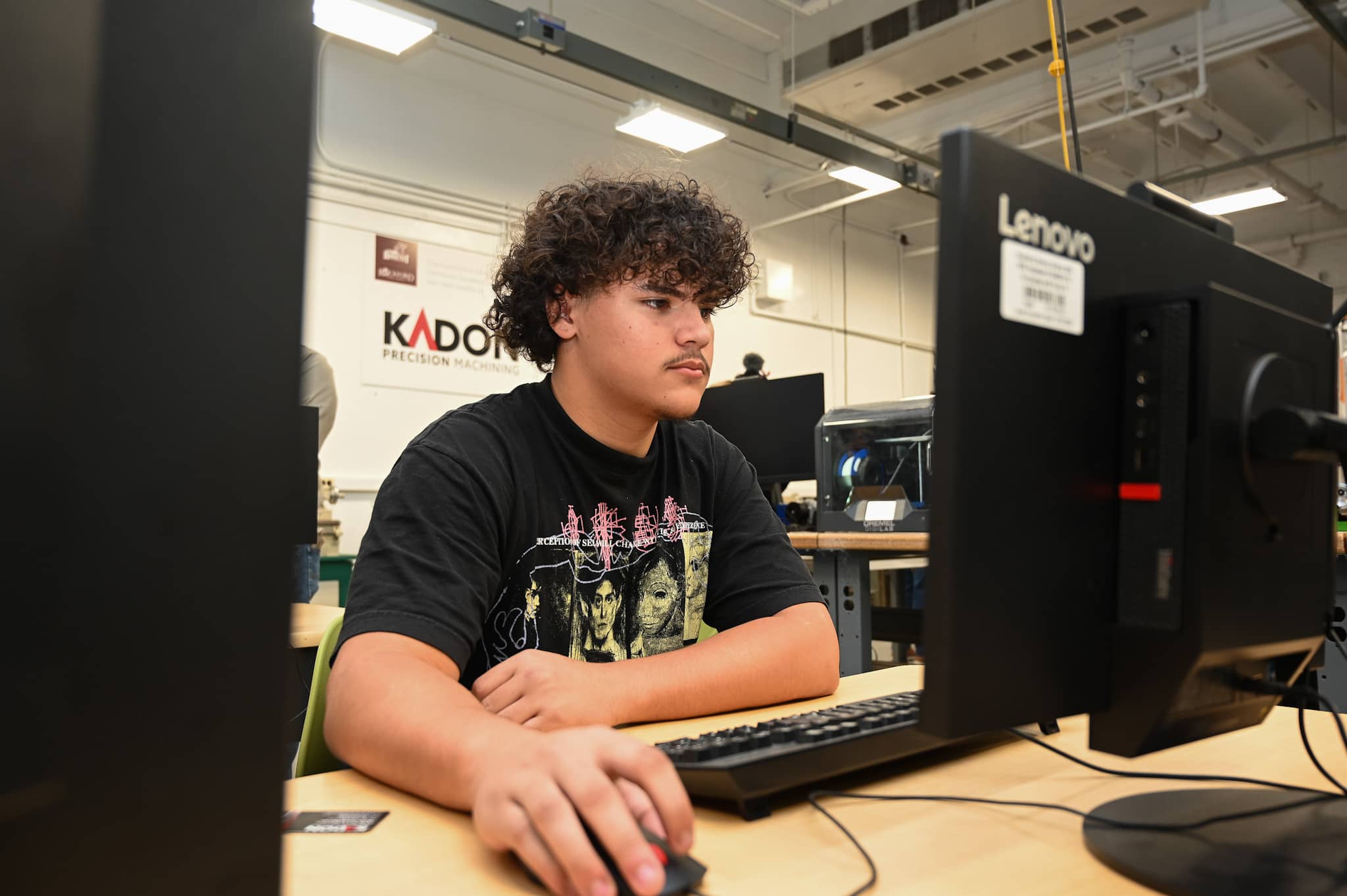

ROCKFORD — Roosevelt Community Education Center on Tuesday unveiled a brighter new manufacturing classroom space intended to better reflect the workplace conditions of modern manufacturing.

The first-floor classroom was renovated to replace fluorescent lights with brighter LED lights, which were also raised to create more space. The bare concrete floors got a new epoxy coat, dark beige walls and ceilings that were splattered with oil were painted white and new workbenches were put in place.

“The way the room was set with how the items in here were being utilized were probably a more 1950s, 1960s vibe,” said David Holder, a machinist with 12 years experience who teaches at Roosevelt. “It was the old, walk into the shop I’m going to get oily and gross all the time, but that’s not what manufacturing today is.”

More education: Rockford Public Schools show progress in literacy, graduation rates. Still lag state average

Roosevelt offers smaller class sizes and more personalized instruction for students who may have struggled with traditional high school or faced hardships that affected their education.

Improving the classroom space is an important aspect to show students a pathway for a future career, said Scott Sevey, director of career and technical education for Rockford Public Schools.

“In order for these students to see a future in this, they’ve got to be able to see what it actually looks like today,” Sevey said. “We were showing them manufacturing from the 1950s, now we’re showing them manufacturing from 2024.”

Scott Jerie, vice president of Jerhen Industries, approached Roosevelt in early spring 2023 with the goal of transforming the space to match modern workplace conditions. Jerhen Industries is one of the partners in the school’s Production Academy. He rallied together other manufacturers including Justin Franklin of Kadon Precision Machining, Lucas Derry of Header Die and Tool and Dan McKee of Rockford Toolcraft to help renovate the space.

The renovations cost about $13,000, and the majority of the work was done by the industry partners.

More news: Inkwell Books & Threads gives downtown Rockton a new place to relax, shop and read

The four companies also are available for a variety of work-based learning experiences for the students. The improvements not only help the students, but it helps the companies with their future workforce.

“It’s important for our community overall,” McKee said. “We’re hoping to gain employees, but also to let students and parents know that manufacturing is a viable career long-term that they can be successful at, often with benefits you can’t find in other industries.”

This article is by Kevin Haas. Email him at khaas@rockrivercurrent.com or follow him on X at @KevinMHaas or Instagram @thekevinhaas and Threads @thekevinhaas